Polymer alloys with Engineering plastics

- Daicel Miraizu continuously design and develop new materials fulfilling various requirements from the market which is ceaselessly getting diversified and sophisticated, applying the advanced knowledge and technology about polymer alloys accumulated in its long history.

| Grade | Features | Line Up |

|---|---|---|

| PA/ABS NOVALLOY A |

|

|

| PBT/ABS NOVALLOY B |

|

|

| PBT/ABS、PBT/PET NOVALLOY B Enhanced surface appearance grades |

|

|

| PC/ABS NOVALLOY S |

|

|

| FR-PC/ABS with non-halogenated flame retardants NOVALLOY S |

with non-halogenated flame retardants | General Purpose Heat resistant GF-reinforced CF-reinforced |

| FR-PC/HIPS with non-halogenated flame retardants NOVALLOY X |

with non-halogenated flame retardants | General Purpose Easy flow |

Applications

| Grade | Applications |

|---|---|

| PA/ABS 『NOVALLOY A 』 |

|

| PBT/ABS 『NOVALLOY B 』 |

|

| PBT/ABS、PBT/PET 『NOVALLOY B Enhanced surface appearance grades 』 |

|

| PC/ABS 『NOVALLOY S 』 |

|

| NOVALLOY X / NOVALLOY S with non-halogenated flame retardants |

|

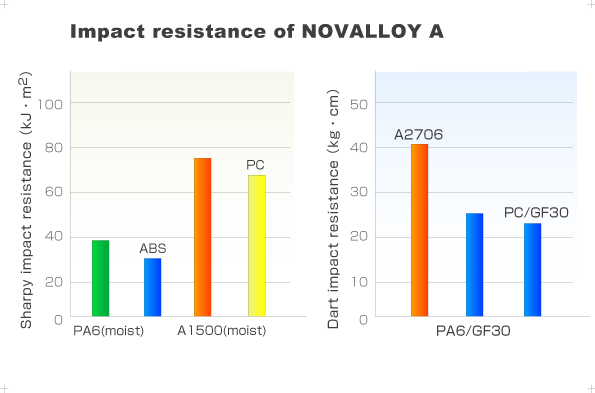

NOVALLOY A / Impact resistance

Alloying of ABS and PA accomplished much higher impact resistance compared to that of each constitutive polymer.

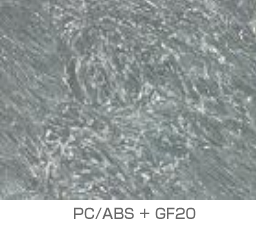

NOVALLOY A / Surface appearance of filled grades

With Novalloy A filled grades you can get highly enhanced surface appearance on their molding surface with very little fiber readout.

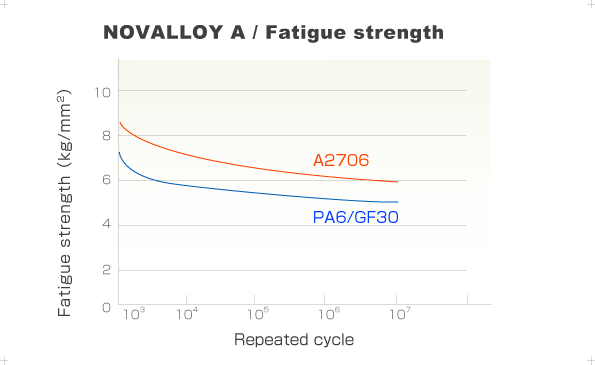

NOVALLOY A / Fatigue strength

- Test method

- Repeated fatigue test ( JIS K 7118 compliance)

- Test condition

- 23℃, 50%RH

- Frequency

- 300 cycles/min.

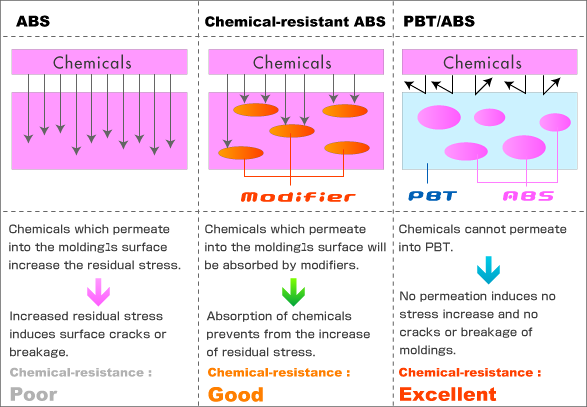

NOVALLOY B / Chemical resistance

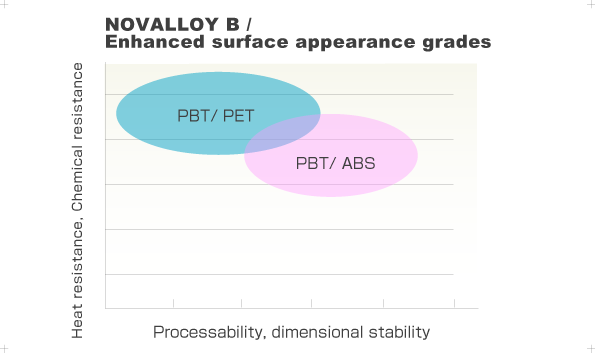

NOVALLOY B / Enhanced surface appearance grades

Novalloy B [ Enhanced surface appearance grades ] is a filled polymer alloy of which surface appearance is highly enhanced by adjustment of the crystallizing rate. Suitable for applications that require both heat resistance and surface appearance.